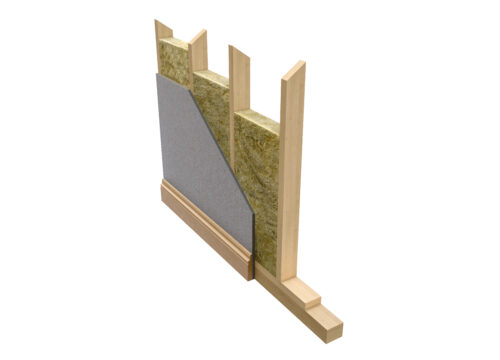

External Wall

-

-

- External Skin ( Block & Render or BricK) – Dependant on clients preference

- Stud positions marked on exterior membrane

- External wall Breather Membrane

- External wall 11mm OSB Sheathing Board

- Studs treated C16, all cut ends Treated (140mmx38mm)

- Sole Plates Treated Timber C16 with DPC fitted

- Mineral wool insulation to achieve required U Value- Site Fitted by others

- Vapour Control Layer airtight membrane- Site Fitted by others

- Continuous PIR foil faced insulation if required to achieve required U Value- Site Fitted by others

- 47mm x 47mm service cavity Battens- Site Fitted by others

- Electric conduits & boxes- Site Fitted by others

- Plasterboard – Site Fitted by others

-

-

-

Internal Wall

-

-

- 89mm or 140mm studs imported CLS C16 treated timber (Available at 400 or 600 c/c)

- 11mm OSB sheeting on racking walls only

- Factory fitted intermediate noggins, timber lintels, base and head rails

- Factory fitted C16 DPC beneath sole plate

- Electric conduits & boxes-Site Fitted by others

- Insulation- Site Fitted by others

- Plasterboard- Site Fitted by others

-

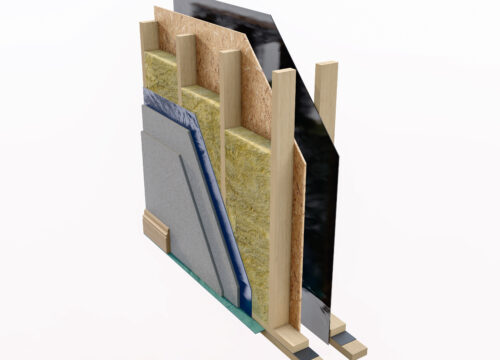

Party

-

-

- 11mm OSB Sheating Board to cavity side of both leaves

- Cavity adequately sealed against fire with Rockwool wired matt used as vertical & horizontal barriers and fire stops. Cavity can be fully insulated if required to achieve zero U Value

- Air tight membrane factory fitted

- Min 40mm cavity between the 2 leaves of the separating wall

- Timber 89mm studs untreated C16, All cut ends Treated

- Sole Plates Treated Timber C16 with DPC fitted

- Insulation – Party walls fully insulated with mineral wool to meet fire & acoustic regulations

- Factory fitted plaster board to meet fire & acoustic regulation

- Factory fitted plaster board to meet fire & acoustic regulations

-

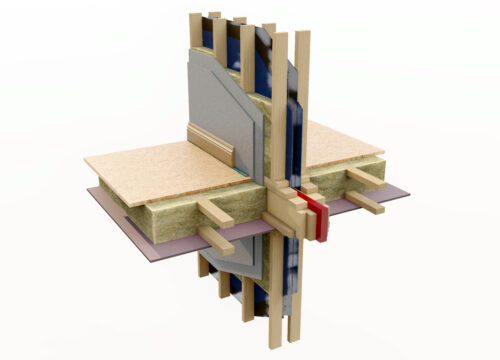

Floor

-

-

- WBS Details 2916-7-506 Construction Details

- Rigid foil faced PIR insulation on external rim beam of floor cassette

- Continuous vapour permeable air barrier membrane wrapped around floor cassette taped to wall

- Floor Joists Factory fitted; 3 options of joists available – Timber / Posi / I-Joists

- Decking board factory supplied & fitted.

- Plasterboard grounds- Site Fitted by others

-

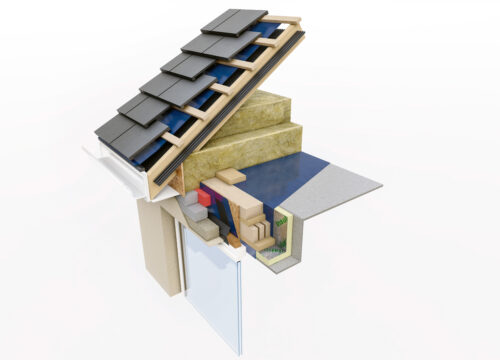

Roof

-

-

- Roof Finishes: Install slating or tiling roof cladding – Site Fitted by others

- Roll out Eaves ventilation system – Site Fitted by others

- Tiling battens

- Breather Membrane

- Backing board for fixing facia, supplied & fitted

- Horizontal cavity barrier and pvc DPC

- Roof Trusses, supplied & fitted

- 35mm x 60mm service cavity Battens to support all board edges – Site Fitted by others

- Airtight membrane – Site Fitted by others

-